Features of the Paksmart PC40 and PC60 range of carton machinery

Australian Designed and Made

quality, support and lower cost spare parts

- to Australian safety and electrical standards,

- use of locally available pneumatics and electrical components.

- Direct support available from the designers and builders on your time zone.

Ease of Operation

directly leads to machine performance and production

- Intermittent motion machine indexing of cartons.

- Allows the operator to concentrate on the product quality and presentation as the infeed bucket (for Automatic Load machines) or the carton is always made ready for loading at the loading or transfer station.

- Load-side carton flaps opened at the load station.

- The operator actions are kept to a minimum simply placing product onto the load table and sliding it in to the waiting carton. No manipulation of the product required to push carton dust flaps out of the way.

- Safety Light curtain and product load check (Only on Hand load PC40).

- This feature is all about safety and operator/machine performance.

- The operator actions are kept to a minimum, simply place the product onto the load table and sliding it in to the waiting carton.

- The load check sensor will automatically cycle the machine while the safety light curtain keeps the operator safe by delaying the machine cycle until safe to do so.

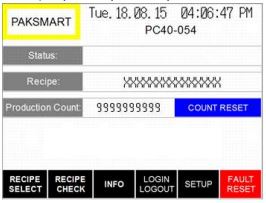

- Colour Touch screen (keeps the operator updated with the machine status).

Black buttons along the bottom of the screen open new pages of information for machine monitoring and settings- “Status” line indicates the machine condition (to ensure rapid machine restarts)

- “Homing” on start-up, “Running”, “Stopped”

- Guard door mapping “status” indicates which guard door is open

- Emergency Stop indication.

- Machine fault conditions in the event of a motor overload.

- Low air indication and machine lock out.

- Inkjet status input, will not allow the machine to start if the inkjet is not ready. This can be overridden when no inkjet is fitted or required.

- Glue at temperature will not allow the machine to start if the glue system is not ready. This can be overridden for machine testing.

- “Status” line indicates the machine condition (to ensure rapid machine restarts)

Ease of Machine Setup

rapid and accurate machine size changes

- Colour Touch Screen press “Recipe Select” load one of the memorised products.

- The new loaded recipe will set:

- production speed

- Glue pattern (skip patterns for glue saving or easy open cartons, full bead glue pattern for maximum holding strength)

- Machine internal cam settings to control all functions of the machine for optimising machine performance.

- The “Recipe Check” mechanical settings to be completed by the operator.

- Once the machine is started the servo driven carton flights will rehome and adjust to the new carton size.

- The new loaded recipe will set:

- From the “Main Page” Press “Recipe Check” and follow the numbered prompts to set the machines numbered adjustments to each of the scaled adjustments.

- Depth adjustment hand crank with digital readout calibrated to carton depth in mm.

- Carton Over Head rails hand crank adjustable with digital readouts calibrated to the carton open width in mm.

- Glue gun height hand crank adjustment with digital readout scaled in mm from bed only adjusted for economy and easy open carton designs.

Ease of Machine Clean Up

- Stainless Steel welded frame and stainless-steel internal walls.

- Debry fall through design in the event of product or carton miss placement the items are able to fall between the drives or outside to the floor for clean up at the end of the production run or shift.

- Top to bottom guard doors on the non-load side of the machine. Allow for ease of access to clean both the machine and the floor. It also an excellent way to service the machine gaining access to critical components easily.

- Machines are mounted on stainless-steel levelling feet and can be lowered on to the fitted cargo castors for moving if required.

Ease of Maintenance

- Extensive use of quality branded components:

- SMC pneumatics

- Omron PLC, photocells and motor systems

- Nordson or Robatech glue systems

- Schneider electrical controls.

- Tsubaki Neptune chains.

- Paksmart components normally available ex-stock.

- Top to bottom Guard doors non-load side for excellent service access to critical components.