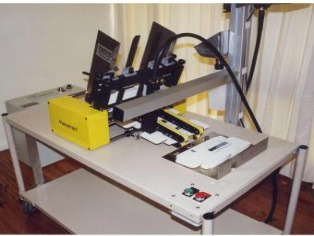

Accurate Friction Feeder

The PF400 is a friction feeder with high-speed and high-accuracy placement, using the latest Servomotor Drive technology. It suits wrapped and unwrapped leaflets, cards, coupons, CDs, and most other flat paper or plastic items.

Our automatic paper feeding mechanism adheres to Australian standards to ensure that all operators who control the machine are safe. The machine uses the finest materials in the packaging industry to ensure that businesses produce top-quality products.

Used by the food and beverage industry, carton manufacturers, contract packers, pharmaceutical industry and mailing industry, Australian made means we can truly customise the PF400′s size range, discharge system and program features to ensure complete customer satisfaction. The PF400 can be operated as a self-contained unit requiring no interfacing or linked to your packaging system for synchronised operation.

The PF400 typically is used for:

- Insertion of cards, leaflets, recipe cards/booklets and many other flat paper or plastic products, wrapped or unwrapped, onto your packaging line. The PF400 friction feeder interfaces with most packaging systems including wrapping machines, cartoning systems and carton folder/gluing machines

- Promotional material insertion for breakfast cereals, snack foods, biscuits/cookies and dairy foods

- Carton manufacturers, for high accuracy placement of wrapped or unwrapped flat items onto carton folder gluing machines

- Pharmaceutical industry uses the PF400 to feed cartons for barcode verification and off line batch coding. Also the inserting of information leaflets into cartons

- Collating is achieved with multiple PF400 feeders for mailing promotions, contract packers and stationery manufacturers

- Tipping and high accuracy placement of promotional material onto magazines for the publishing and printing industries

Features Include:

- High-speed operation maximises your production rates. Speeds of over 400 pieces/min. achievable

- Reduce turnaround time with quick size change and high-speed operation

- Modular construction offers flexibility in the size and thickness range of inserts

- High accuracy placement ensures highest quality product presentation

- Quick size change. No tool adjustment

- Special twin delivery belt system 250 mm in length, with top and bottom drive

- Rugged corrosion resistant construction

- All components are sourced in Australia and readily available ensuring fast, cost effective parts and service

- Continual reverse drive O-ring stripping rollers separate product while the twin belts aid product stability

- HMI display with menu driven controls for ON/OFF, count and speed settings

- Magazine height – 600 mm

- “One-touch” load feature

- The PF400 friction feeder can be operated as a self-contained unit needing no interfacing or linked to your packaging system for synchronised operation

- Compact, easy to move from one application to another

Since 1993, PakSmart Machinery has been manufacturing high-quality packaging machines that execute different packaging processes. Our personnel has extensive experience in designing, assessing, advising and implementing packaging solutions to meet the expectations of their customers. We help businesses reach their goals in packing their products.

To know more about our wide range of packaging materials, call +61 2 9630 9464 or fill out our contact form.

>

Complete the below to receive additional product specifications.