“Shelf ready packaging” (SRP) is also known as “retail ready packaging” (RRP).

It refers to the box the individual goods come in, which can then be used as a display/stand at store level.

Using shelf-ready packaging allows for a more efficient replenishment of goods at store level and contributes to improved product availability for your customers, which in turn results in greater product sales.

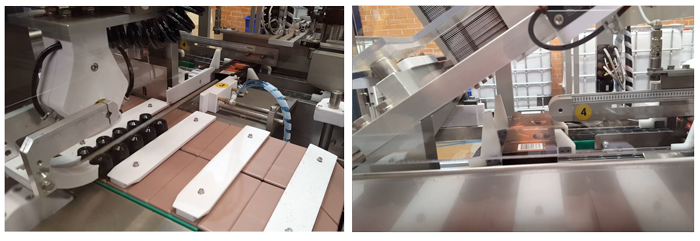

PAKSMART’s recently released an automation project for a shelf ready case system for corrugated packaging.

We’ve now followed this up with a shelf ready carton system using fibre board.

In both cases, the challenge we needed to overcome was to handle a greatly weakened container, load it with product and transfer through the pack, flap folding and sealing process.

Paksmart PC40SR Corrugated Case System

Our PAKSMART PC40SR corrugated case system does this using a two stage case erecting process. Firstly, we remove the case from the powered magazine and then we open the case at a staging point between the magazine and the carton flights.

Whilst this did slow down the overall packing process by adding an additional stage in the erecting process, the PC40SR corrugated system can still cycle at over 25 cycles per minute.

Our customer was able to effectively run the line at over 100 bottles per minute, packing into a 4 pack shelf ready case.

Typical corrugated cases are very resistant to opening and with the weakened panels, they can easily be ripped apart by a typical pull apart erecting process. The gentle erecting process of our PAKSMART two stage erector handled a range of sizes with ease and efficiency, without detriment to the packing.

The PAKSMART PC40SR can be sized changed in minutes with most settings either computer adjusted or hand crank adjusted with scales. Our customer was very happy with the system; including rapid setup and going into full production with less than a day’s commissioning onsite.

Paksmart PC40SR Fibre Board Shelf Ready Carton System

The PAKSMART PC40SR fibre board shelf ready carton system is currently running products for personal care and pharmaceutical products.

Once again, the weakened board with the zipper easy tear across 4 panels made carton erecting and folding a real challenge. However, the servo motor controls allowed for gentle acceleration of the carton through the folding ploughs, reducing the load taken by the carton flaps and saving the panels from breakage.

In both cases, these packs are to form part of the shop display. It’s therefore important that the packaging not only remains intact for delivery into store, but alos that the packaging presents well on the shelf.

The PC40SR systems glues the ends of the shelf ready packs, providing strength to the container, whilst the program controlled compression system produces a quality presentation with squared ends on shelf ready pack.